MBU- Micro Bubble Generator Unit

Product Description

The floatation gas is injected into the pressured backflow in the form of micro bubbles. Through cutting and screening from the micro bubble generator, the backflow is transferred into

high-quality gas-dissolved water with tiny uniform sized bubbles, thus to realize higher purification efficiency.

This product has the advantage of compact structure and could serve the fields like oil &gas field, refinement, coal chemical industry, steel industry, printing & dyeing plant, papermaking,

city administration etc. In oil& gas field, this unit could produce gas-dissolved water for sinking tanks and inclined plate deoiling devices to increase the oil elimination efficiency; This unit could also work as technical upgrading for current water treatment

devices for reducing cost and energy; In alga control, it can contribute to purify and renovate the cityscape water body as well.

Advantages

1) Unique technology for refining, cutting, screening bubbles , which makes dense, uniform-sized micro bubbles;

2) Less backflow water (Usually 10% of the system capacity) that decrease the construction cost, energy consumption and gas emission;

3) Simple installation with easy maintenance and stable performance;

4) Compact skid module that saves space.

MRF-Micro Bubble Rotating Floatation System

Product Description

Micro Bubble Rotating Floatation System(MRF) is composed of the Micro Bubble Generator Unit(MBU) and the Rotating Floatation Separator. The gas dissolved water with micro bubbles from the generator mixes with the oily water inside of the separator, in which the micro bubbles

collide and adhere with dispersed oil drops, floating polymer and form the oil-gas aggregates. As the water pressure decreases, the micro bubble dilates and the oil-gas aggregates float up to the surface, thus to separate from water and finally purify the water.

MRF is an advanced and mature separation technology to eliminate impurities like oil drops, suspended particles, short fibers, algae etc. It has the characters of high efficiency, stable

performance, less volume or space and has been widely used on platforms, FPSOs and oil &gas sewage treatment. Besides, MRF successfully serves to deal with sewage with polymers and sewage

from refinement, coal chemical industry, steel industry, printing & dyeing plant, papermaking, city administration, mine exploration etc. In alga control, it can contribute to purify and

renovate the cityscape water body as well.

The supporting Micro Bubble Generator has two types of model: Injecting Type and Suction Type; the rotating floatation separator could normally work with or without pressure.

Advantages

1) High separation efficiency and large capacity; The surface loading rate can reach at 60 m3/(m2·h) , and for sewage with over 500ppm oil content, its elimination rate could be over 97%;

2) Using micro bubbles to adhere particles; The adherence is loyal and back mixing is barely seen;

3) Less floatation agent consumption; Compared with normal floatation, over 1/3 agent could be saved;

4) No mechanical transportation, which is energy-saving, stable and easy to maintain;

5) The rotating field could pushes the oil drops to collide and adhere with the micro bubbles, which is suitable for oily sewage treatment.

MHF-Micro-Bubble Horizontal Floatation System

Product Description

WHF is composed of MBU and Horizontal Floatation Unit. The dissolved water with micro bubbles from MBU goes through the release device and distributes uniformly into the cross section of the inlet oily water. As the water pressure decreases, the oil-gas aggregates formed by micro bubbles adhering with oil drops and suspended particles then puff and float up to the surface as dross. That’s how the separation realizes. In this process, the floatation unit could work with or without pressure and its shape could appear as column or cube. The discharge ways could be overflow discharge, sludge scraper and sludge scraper & conveyer.

This technology could be used to separate water from impurities like oil, suspended particles, short fibers, and alga, after which the purified water could be discharged or reused according to standards. This technology could engaged in the following fields: Offshore platform, oily water with polymer, industry water treatment including oil &gas field, refinement, coal industry, steel industry, printing and dyeing, papermaking, city administration and mine exploration. Besides, in alga control, landscape water body renovation and solution of sewage with emulsified oil, it has good performance as well.

Advantages

1) Using supersaturated dissolved gas and high efficiency rotating cutting technology to produce the dissolved water with micro bubbles;

2) Using stable release technology to arrange the dissolved water with micro bubbles in balanced pressure and balanced flow rate;

3) Intensified mixing and flocculation to boost efficiency of chemicals’ effect;

4) Stream rectification and stabilization provide well-proportioned separation field;

5) Multi-stage floatation in a single tank.

HHC- Hyper Hydro Cyclone

Product Description

Hyper Hydro Cyclone could be used to deal with all kinds of sewage from oil& gas field and refining and chemicals plant.

Pulled by centrifugal force generated from the guiding structure, two streams with different densities will separate from each other. This is how Hyper Hydro Cyclone works.

Advantages

Hyper Hydro Cyclone from Veritas-MSI is unique as its core stream channel is designed according to severe hydro mechanical model. After computer simulation and structure optimization, the final design has the advantages of less resistance, environmental flexibility and high separation efficiency.

1) Optimized inlet structure and upgrading of internal channel’ s material reduce the washing and corrosion influence;

2) High machining and assembling precision guarantees the separation efficiency;

3) Simple design leads to easy maintenance.

Key Index

Differential pressure loss from inlet to outlet: 300~500 kPa;

Inlet oil content at 1000~10000 ppm, oil elimination rate>95%;

Inlet oil content at 500~1000 ppm, oil elimination rate>90%;

Inlet oil content at 100~500 ppm, oil elimination rate>80%;

The actual elimination rate may fluctuate according to characters and size of the contented oil.

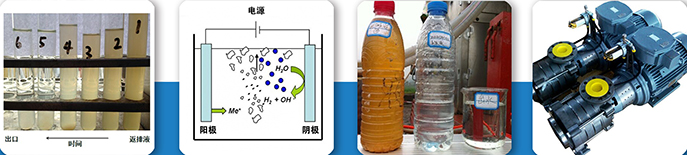

MEC-Mobile Electro-coagulation System

Product Description

Electro-coagulation is an emerging technology that uses “sacrificed” anode in-situ to form metal hydroxide coagulants with highly concentrated charges, and those coagulants shall neutralize the surface charges of the oil, colloids and suspended particles. At the same time, the redox and oxidation feature of the coagulants could destabilize and separate these impurities like colloid particles, COD, heavy metal ions and bacteria. Electro-coagulation System is normally used to deal with all kinds of oil &gas sewage like fracturing liquid, acid liquid, well repair& washing liquid. After treatment, the sewage could finally meet the relative standards for discharge or reuse. Besides, it is engaged in pretreatment of wastewater from chemical industry, electroplating process, coking process etc to strengthen their biodegradability.

Advantages:

1) Using advanced pulse-electro coagulation to reduce passivation of the polar plate; Lower the energy cost and plate consumption through technical upgrading;

2) Mobile compact module design takes less space and more flexibility;

3) The electrolysis of in-situ oxidation smoothly produces high-activity floccules which can accelerate the process of destabilization and flocculation; Electrolytic reduction brings a large number of micro bubbles, which naturally lead to floatation effect and lift the dross to the surface.

4) The electric field action could promote the movement of those tiny colloid particles and strengthen flocculation reaction; it can get rid of the color, smell, colloid particles, COD, oil, heavy metal ions etc as well.

5) Compared with the traditional chemical flocculation, MEC needs less chemicals and produces less ions at the outlet; As a result, rare second pollution may come up and sludge output is 2/3 less than traditional process.

6) Easy to maintain and flexibility to water conditions.