Oil-Water Separation Membrane

Oil-Water Separation Membrane (Oil-Water Filtration)

1. Material Introduction

Dual-Super New Material Coalescing Filter Membrane

Dual-Super new material coalescing filter membranes are available in two types: ceramic membranes and stainless steel cartridges.

Ceramic Membrane Components

- High durability

- Chemical resistance

- High temperature tolerance

Stainless Steel Cartridge

Stainless steel cartridges offer robustness and are ideal for applications requiring high mechanical strength and chemical stability. They are reusable and can withstand high pressures and temperatures.

Stainless Steel Cartridge Components

- Robust construction

- High mechanical strength

- Chemical stability

- Reusability

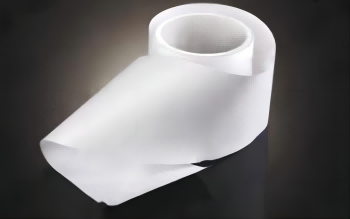

Fiber Membrane

Fiber membranes are lightweight and provide high surface area-to-volume ratios, enhancing separation efficiency.

Dual-Super Material Properties

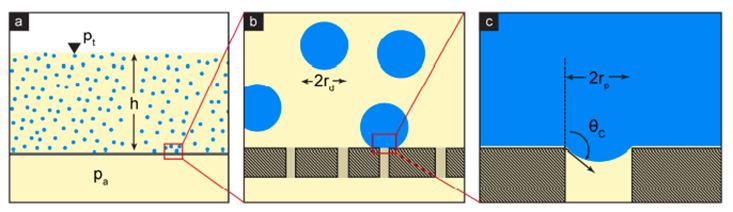

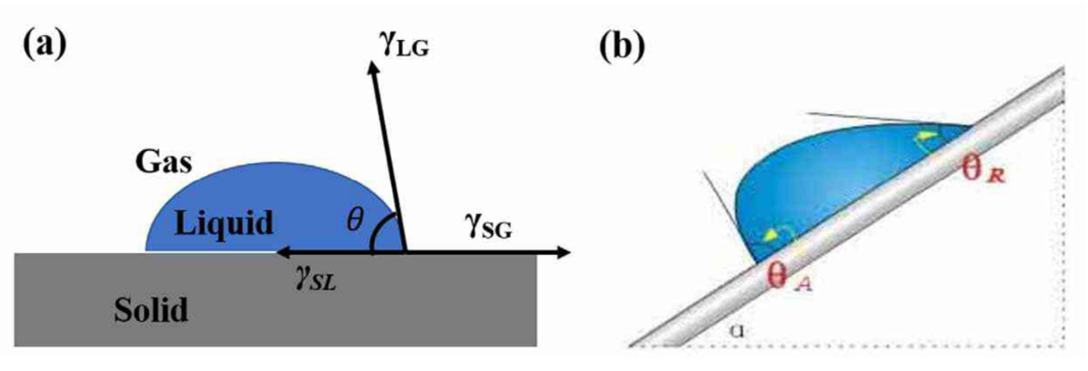

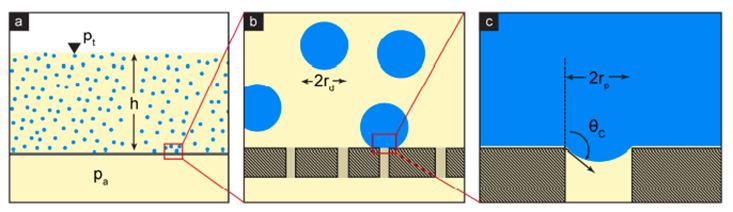

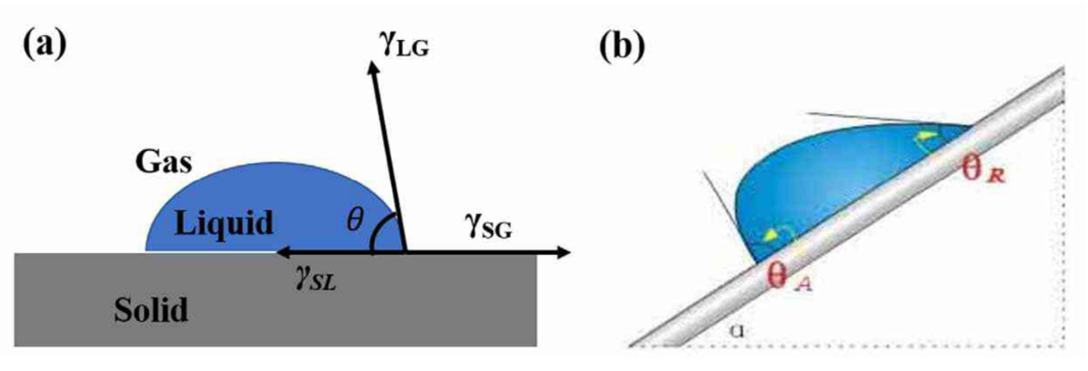

Dual-Super materials alter the wettability of surfaces by changing the intermolecular attraction (surface tension), which helps in oil-water separation. These materials have a stronger repulsion for oil molecules compared to water molecules. When an oil-water mixture passes through the Dual-Super material, the material adds extra resistance to oil droplets, allowing water droplets to pass with lower resistance. This property is particularly useful for separating emulsified oils, achieving demulsification and coalescence.

Key Principles

1. Continuous Phase Wettability Greater Than Dispersed Phase

2. Dispersed Phase Particle Size Larger Than Pore Size

3. Pressure Less Than Breakdown Pressure, Leading to Separation of Continuous and Dispersed Phases

Advantages

1. Excellent Hydrophilic and Oleophobic Properties

2. Higher Contact Angle

3. Higher Breakdown Pressure

4. Smaller Oil Droplet Size

5. Lower Membrane Usage

6. Higher Flux

7. Higher Operating Membrane Pressure

2. Material Application

Dual-Super Swirl Coalescing Filtration Technology (Operational Schematic)

1. Good Shock Resistance

2. Low Water Content in Oil Output

3. Full-Tank Operation Mode

Benefits

1. Small Footprint

2. Low Equipment Cost

3. Simple Operation

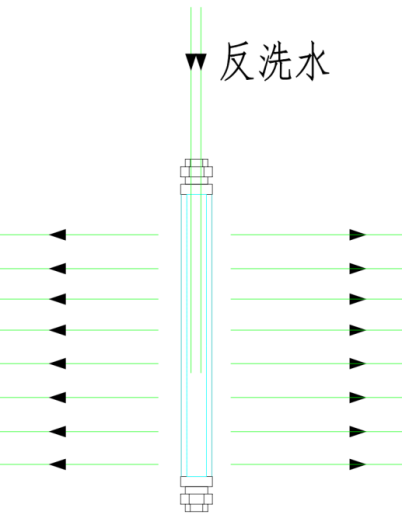

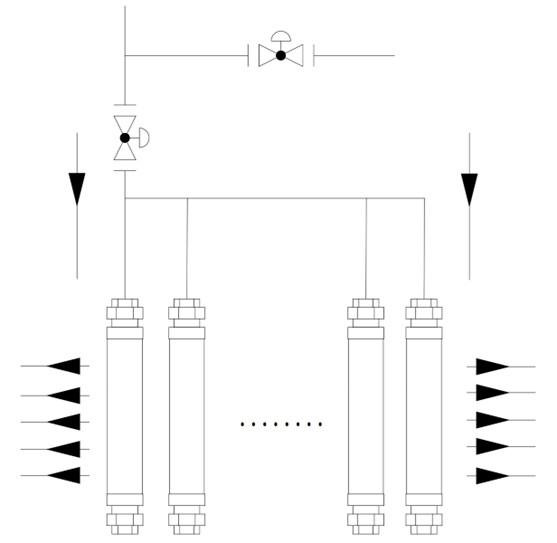

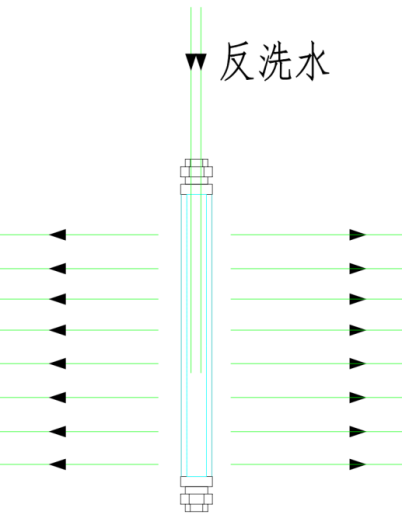

Backwashing Principle (Schematic)

The backwash selector consists of components such as inlet branch pipes, outlet manifold, frame, valve body, rotating arm, valve stem, coupling, packing, and an electric controller. It is primarily used to automatically select branches for backwashing during the backwash cycle.

The backwash selector has 8 inlet ports, 1 outlet manifold, and 1 backwash inlet. During normal operation, the coalescing tank divides the inflow into 8 paths entering the backwash selector, which then directs the water out through the manifold. During backwashing, the backwash inlet rotates to select the appropriate inlet branch pipe for backwashing, with controllable backwash duration and intensity.

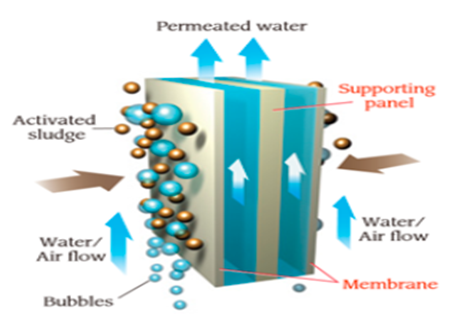

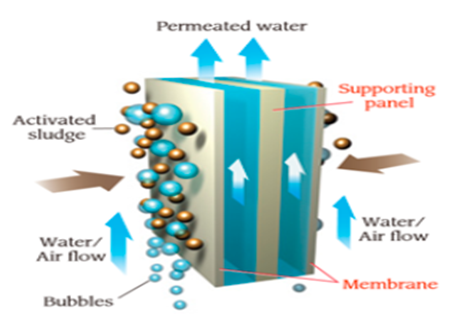

Cross-Flow Microbubble Cleaning Dynamic Structure Design

The cross-flow microbubble cleaning dynamic structure design ensures that gas, liquid, and solid flow directions differ, as shown in the diagram. Microbubbles rise along the filter membrane, lifting solid pollutants from the surface of the membrane, reducing the frequency of membrane fouling and decreasing the need for backwashing.

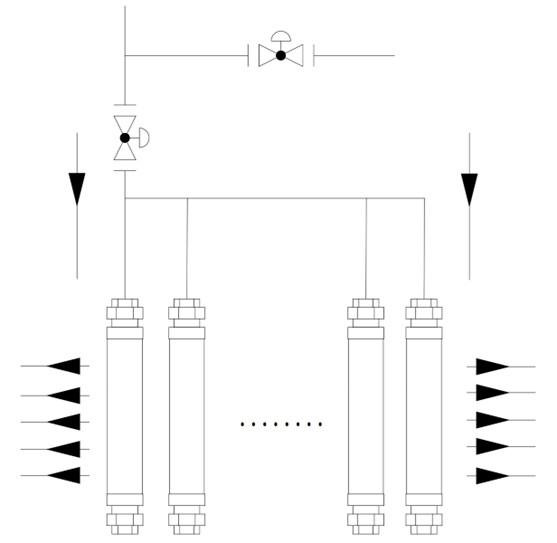

System Configuration

The system operates with multiple coalescing filter cores/ceramic membranes running in parallel. Backwashing is performed using air washing/water washing. During backwashing, one group is backwashed while others continue normal operation, enabling online backwashing.

Process Description

1. Inflow and Dissolved Air Water Mixing: Inflow mixes with dissolved air water before entering the tank. Oil and suspended solids in the wastewater float to the oil collection bucket due to the action of microbubbles. The oil output is controlled by a level gauge linked to a regulating valve.

2. Gas Phase Space: The top of the dual-super coalescing tank is designed with a gas phase space for maintaining pressure and supplying air to the dissolved air pump.

3. Filter Membrane Group: Each coalescing tank is equipped with a filter membrane group divided into 8 sections. Outflow enters the backwash selector, where 7 sections operate normally while 1 section is backwashed. The outflow is collected in the manifold. The tank is equipped with a level gauge linked to an outflow regulating valve to control the outflow rate.

4. Backwashing: Backwash water is taken from the outflow of the backwash selector and used for intermittent backwashing of the 8 coalescing membranes. The dissolved air pump draws water from the tank and uses nitrogen as the gas source. The dissolved air water is partially used for floating oil droplets and suspended solids and partially for forward washing.

This system ensures efficient and continuous operation, minimizing downtime and maximizing the lifespan of the filter membranes.

Contact Information : Ye Zilong Phone: +86-133-8667-7776

Email: zilong.ye@vtechcn.com

Contact Information : Wang Jianrong Phone: +86-133-2612-8487

Email: jianrong.wang@vtechcn.com

1. Material Introduction

Dual-Super New Material Coalescing Filter Membrane

Dual-Super new material coalescing filter membranes are available in two types: ceramic membranes and stainless steel cartridges.

Ceramic Membrane

Ceramic Membrane Components

- High durability

- Chemical resistance

- High temperature tolerance

Stainless Steel Cartridge

Stainless steel cartridges offer robustness and are ideal for applications requiring high mechanical strength and chemical stability. They are reusable and can withstand high pressures and temperatures.

Stainless Steel Cartridge Components

- Robust construction

- High mechanical strength

- Chemical stability

- Reusability

Fiber Membrane

Fiber membranes are lightweight and provide high surface area-to-volume ratios, enhancing separation efficiency.

Dual-Super Material Properties

Dual-Super materials alter the wettability of surfaces by changing the intermolecular attraction (surface tension), which helps in oil-water separation. These materials have a stronger repulsion for oil molecules compared to water molecules. When an oil-water mixture passes through the Dual-Super material, the material adds extra resistance to oil droplets, allowing water droplets to pass with lower resistance. This property is particularly useful for separating emulsified oils, achieving demulsification and coalescence.

Key Principles

1. Continuous Phase Wettability Greater Than Dispersed Phase

2. Dispersed Phase Particle Size Larger Than Pore Size

3. Pressure Less Than Breakdown Pressure, Leading to Separation of Continuous and Dispersed Phases

Advantages

1. Excellent Hydrophilic and Oleophobic Properties

2. Higher Contact Angle

3. Higher Breakdown Pressure

4. Smaller Oil Droplet Size

5. Lower Membrane Usage

6. Higher Flux

7. Higher Operating Membrane Pressure

2. Material Application

Dual-Super Swirl Coalescing Filtration Technology (Operational Schematic)

1. Good Shock Resistance

2. Low Water Content in Oil Output

3. Full-Tank Operation Mode

Benefits

1. Small Footprint

2. Low Equipment Cost

3. Simple Operation

Backwashing Principle (Schematic)

The backwash selector consists of components such as inlet branch pipes, outlet manifold, frame, valve body, rotating arm, valve stem, coupling, packing, and an electric controller. It is primarily used to automatically select branches for backwashing during the backwash cycle.

The backwash selector has 8 inlet ports, 1 outlet manifold, and 1 backwash inlet. During normal operation, the coalescing tank divides the inflow into 8 paths entering the backwash selector, which then directs the water out through the manifold. During backwashing, the backwash inlet rotates to select the appropriate inlet branch pipe for backwashing, with controllable backwash duration and intensity.

Cross-Flow Microbubble Cleaning Dynamic Structure Design

The cross-flow microbubble cleaning dynamic structure design ensures that gas, liquid, and solid flow directions differ, as shown in the diagram. Microbubbles rise along the filter membrane, lifting solid pollutants from the surface of the membrane, reducing the frequency of membrane fouling and decreasing the need for backwashing.

System Configuration

The system operates with multiple coalescing filter cores/ceramic membranes running in parallel. Backwashing is performed using air washing/water washing. During backwashing, one group is backwashed while others continue normal operation, enabling online backwashing.

Process Description

1. Inflow and Dissolved Air Water Mixing: Inflow mixes with dissolved air water before entering the tank. Oil and suspended solids in the wastewater float to the oil collection bucket due to the action of microbubbles. The oil output is controlled by a level gauge linked to a regulating valve.

2. Gas Phase Space: The top of the dual-super coalescing tank is designed with a gas phase space for maintaining pressure and supplying air to the dissolved air pump.

3. Filter Membrane Group: Each coalescing tank is equipped with a filter membrane group divided into 8 sections. Outflow enters the backwash selector, where 7 sections operate normally while 1 section is backwashed. The outflow is collected in the manifold. The tank is equipped with a level gauge linked to an outflow regulating valve to control the outflow rate.

4. Backwashing: Backwash water is taken from the outflow of the backwash selector and used for intermittent backwashing of the 8 coalescing membranes. The dissolved air pump draws water from the tank and uses nitrogen as the gas source. The dissolved air water is partially used for floating oil droplets and suspended solids and partially for forward washing.

This system ensures efficient and continuous operation, minimizing downtime and maximizing the lifespan of the filter membranes.

Contact Information : Ye Zilong Phone: +86-133-8667-7776

Email: zilong.ye@vtechcn.com

Contact Information : Wang Jianrong Phone: +86-133-2612-8487

Email: jianrong.wang@vtechcn.com

Products & Solutions

- Metering Module

- Wellhead Monitoring Skid

- Single Well Metering Ski

- Oil-Water Separation Mem

- Slug Catcher

- Vane Type Separator

- Filter cartridge

- GLCC Desander System

- Water Treatment Module

- Micro-Bubble Flotation T

- Hyperbolic hydrocyclone

- Gas dissolution pump

- Mobile Electrocoagulatio

- Mechanical foam eliminat

- Chemical Injection Skid